Tube Laser Cutting

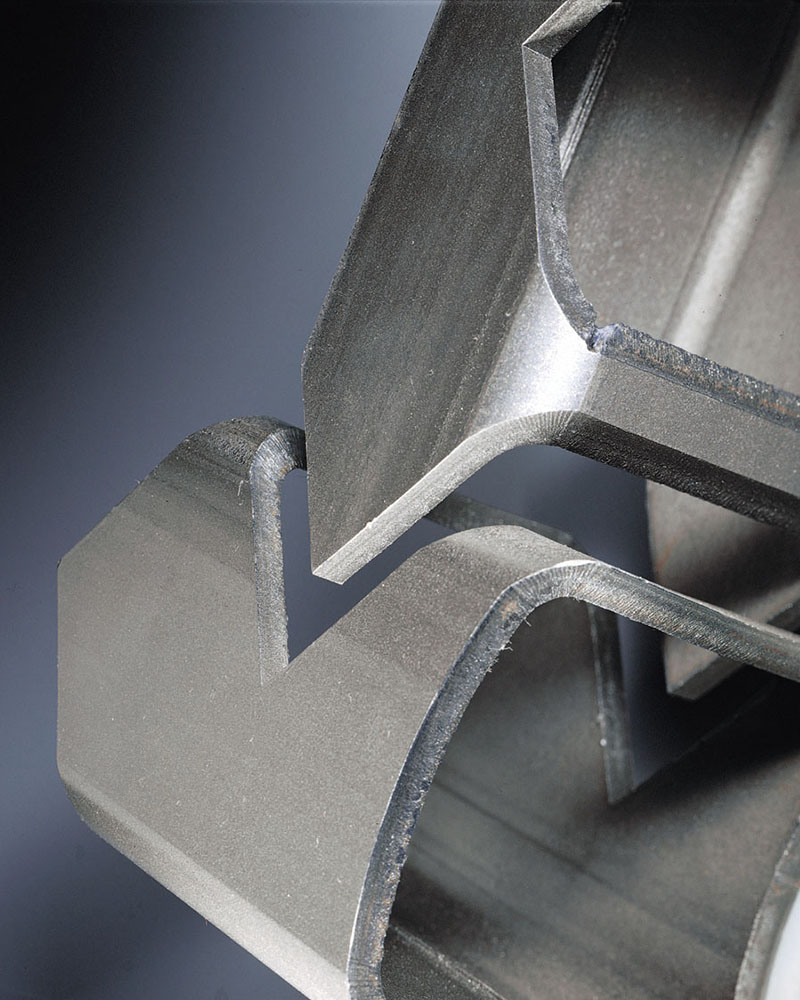

Our tube laser cutting machines can create any shape of slots and holes in round tubing with diameters from 12mm to 152mm, and in square tubing with side dimensions up to 120mm. They are also capable of laser cutting box sections and most open profiles, such as angles and channels.

Tube Laser Cutting

Laser Cutting Mild Steel Tube

Max Thickness: 12mm

Laser Cutting Stainless Steel Tube

Max Thickness: 8mm

Laser Cutting Aluminium Tube

Max Thickness: 8mm

Laser Cutting Copper Tube

Max Thickness: 5mm

Laser Cutting Brass Tube

Max Thickness: 8mm

Tube Laser Cutting Services

Advantages of Laser Tube Cutting

Explore the myriad benefits of tube laser cutting, offering precision, versatility, speed, and efficiency, ideal for intricate designs and rapid production.

Variety

Round, square oval and rectangular sections

Materials

Wide variety of materials

Clean Cuts

Any size & shape of cut can be made both at the ends and anywhere along the length

Multiple Cuts

Multiple cuts in a single cycle

Round Tube

Round Tube 12mm to 152mm O/D x up to 6500mm long

Square/Rectangular

Square/Rectangular Tube 12mm to 1200mm side x 6500mm long

Automation

Automatic feed for speed and efficiency

Cost-Effective

No tooling costs

Laser Cutting Services

Tube Cutting

Laser Box Cutting

Angle & Channel Cutting

Laser Profiling

We offer precision laser profiling for custom shapes, intricate designs, detailed cuts, and exacting standards.

Cutting Head

3D

Tube Cutter

Tubes and Profiles up to

23kg/m

in weight

Tubes Cutting From

18 mm to 152,4 mm

in diameter

Laser Profiles use ISO 9001:2015 to drive production, ensure full traceability and satisfy customer needs

At Laser Profiles, we are committed to delivering top-notch engineering and fabrication services. Our focus on quality is demonstrated by our accreditation to the latest standards and our meticulous in-house QA team that inspects every component. Our mission is to go beyond meeting the needs and expectations of our clients.

With a wealth of experience, we serve a wide array of industries, such as aerospace, defense, nuclear, marine, and oil & gas.

Frequently Asked Questions

Tube laser cutting is a process that uses a laser to cut and shape tubes and hollow sections of various materials, such as metal. This method is highly precise and efficient, allowing for the creation of complex designs and shapes that would be difficult or impossible to achieve with traditional cutting methods. Tube laser cutting is commonly used in industries such as automotive, aerospace, construction, and furniture manufacturing, where precise and intricate cuts are required. The process is controlled by computer numerical control (CNC) systems, ensuring consistent quality and accuracy.

Tube laser cutting offers numerous benefits, including high precision and accuracy, allowing for complex and intricate designs. It is highly efficient, reducing production time and costs while minimising material waste. The process is versatile, capable of cutting various materials and shapes, and it ensures consistent quality through computer numerical control (CNC) systems. Additionally, tube laser cutting reduces the need for additional machining or finishing, improving overall productivity and reducing labour costs. Its non-contact nature also prevents material deformation and contamination, making it an ideal choice for industries requiring precise and clean cuts.

- Stainless Steel

- Mild Steel

- Aluminium

- Brass

- Copper

- Bronze

We can laser cut tubes of diameters ranging from just 18 mm to 152,4 mm.